This article will give you different suggestions on how to start looking at your products relevant for the EUDR.

When implementing your strategy to comply with the European Union Deforestation Regulation (EUDR), determining where to begin can feel overwhelming. The key to a successful start is to focus on the right products and suppliers. By strategically selecting which products to map first, you can ensure that you’re gathering relevant and actionable data while optimizing your efforts to meet EUDR requirements. In this guide, we’ll walk you through the first steps to identify and prioritize the products that should take precedence in your compliance journey.

Adopting a structured approach to ensuring production continuity is key to making the due diligence process more manageable and ensuring efficient EUDR compliance. It ensures that key products are prioritized, helping to maintain a continuous production of your company’s goods.

Product based Supplier Sampling

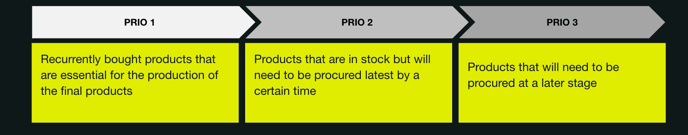

Product-based supplier sampling focuses on prioritizing specific high-risk products and their associated suppliers. The following approach is clustered in 3 different priorities and described further in detail below:

PRIO 1 - Prioritize Key Products

Begin by identifying the most critical products for your business, particularly those that are purchased recurrently. For example, if an automotive manufacturer uses the same components across multiple car models, these parts and their respective suppliers should be prioritized. As these items are essential not only for the production process but also for the final product, focusing on them early will help ensure that key components are addressed effectively.

PRIO 2 & 3 - Focus on Priority Orders

Start by concentrating on orders from the first quarter, particularly for products that are regularly purchased and crucial to the production of your final products. Next, prioritize replacement orders for Q1, which are products that are currently in stock but will need to be replenished by a specific deadline. Lastly, focus on Q2, Q3, and Q4 orders that are essential but can be procured at a later stage.

Knowledge - Building Approaches

Another possibility to start your EUDR approach can be by either focusing on mature suppliers first or defining a smaller scope. Both of those approaches are explained below:

Focus on Mature Suppliers First

Another option for supplier sampling is to start with established suppliers. If you know of a supplier that is already EUDR ready, meaning they have a Due Diligence System in place and can provide Due Diligence Statements, it makes sense to prioritize them. Since established suppliers are likely to meet the necessary requirements more quickly, this approach can serve as an educational strategy, providing you with a foundation for understanding how EUDR compliance is achieved.

Define a Smaller Scope

If you don't have specific high-priority parts, you can narrow your focus by region. Focus on two countries within the EU, where your key suppliers are located. From there, you can assess suppliers from non-EU countries in these regions. Once you’ve addressed these, expand your focus to all EU suppliers, and finally, as the last step, tackle non-EU suppliers from all regions to ensure a comprehensive supplier management process.